Video :

Video :

Xinda Co-Rotate Twin Screw Masterbatch Line

Lab. Type Co-Rotate Twin Screw Extruder Line

Corotate Twin Screw Compounder Photo Album

Applications;

•Masterbatch

•Thermoplastic

•Elastomer

•Thermoset

•Flame Reterdant Compound

• PVC Compound

•Powder Coating & Toner

• Wire & Cable Compound

• Food Applications

• Special Products, vb... |

|

XINDA Co-Rotate Twin Screw Extruder Systems

|

| ... |

High Torque / High Speed

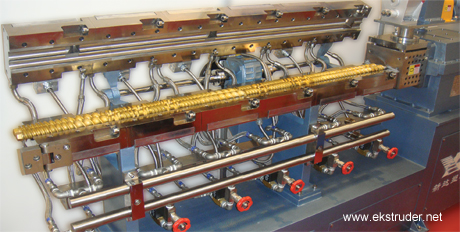

Openable Barrel / Modular System

XINDA has proven itself on twin screw extruder production besides Co-Kneader technology. We produce turnkey compound and masterbatch production lines according to our customers' requests. There are hundreds Xinda twin screw running lines over the world on different applications.

In 2016, we made 600rpm and 800rpm high torque twin screw extruders our standard producion instead of 500rpm normal torque systems. We are using special design high resistance materials for the key parts such as screws, liners of high speed & high torque extruders. Also we can equip these high speed & high torque extruders with reliable Chineese gearbox or Henschel gearbox imported from Germany according to our customers' requests. Chineese gear box is high quality and have been tested by Xinda for years. One of the leading gearbox manufacturer Henschel is producing the twin screw extruder gearbox since 1972. Also, according to customers' request, we can equip with the security coupling Mayr (German) or Bibygard (England) brands.

PSHJ Co-Rotate Twin Screw Extruder Main Applications:

- Mixing of additives and pigments,

- Reinforcement,

- Preparation of Fillers / Additives,

- Shear and temperature sensitive compounds such as PVC, XLPE, v.b.,

- Degassing of volatile components

Modular Design

XINDA twin screw extruders are designed as a completely modular system. Users can make different applications by small configuration changes. All you need to change some screw and barrel parts for new applications.

Horizontal Openable Barrel Design

The barrel can be open in a few minutes. So, the cleaning of inside, maintenance and changing of application will be so easy. So, the spent time and waste materials will be minimize.

Barrel Section- Separately controlled

The modular principle of the barrel permits different precise sequencing for each application. Each barrel section's temperature can be set separately. Electrical heater shells provide for heating, cooling is obtained with water. Barrels, as well as screw and kneading elements are made out of nitride steel in the standard version; the wear resistant version is made of suitable materials, corresponding to the respective requirements.

Standard Barrels

The freely selectable order of screws and kneading elements assure the process sections matching the process configuration. Thus, different process zones can be set up interchangeably, according to the requirements for: Conveying; Plasticizing; Mixing and Shearing; Homogenizing; Degassing; Pressure building

Spare Part & Aftersale Service

We showed our service quality for supplying the spare parts and after sale service to our customers in the past years. Also, we are offering a better service quality for the vital parts (screw, pin, etc.) through the warehouse in Turkey.

XINDA has a very big spare part warehouse. Xinda can send majority of the spare parts within 24 hours by courier after getting confirmation from the buyers. Also, if the required spare part is a vital part such as screw, pin, etc. Xinda will send it within 1 hours by courier after getting confirmation from the buyer.

Xinda provides with life time service for all the parts on the machine.

All components are manufactured in OEM quality and compatibility guarantee. Material options; chrome steel, nitrided steel, bimetallic etc.

|

|

|