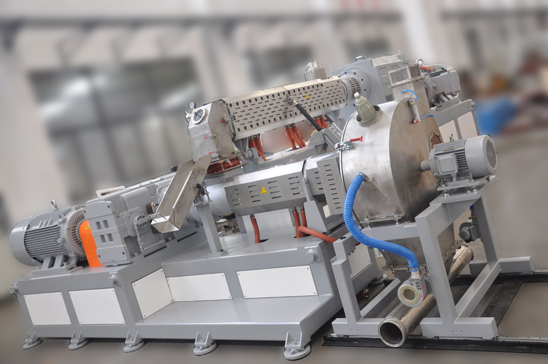

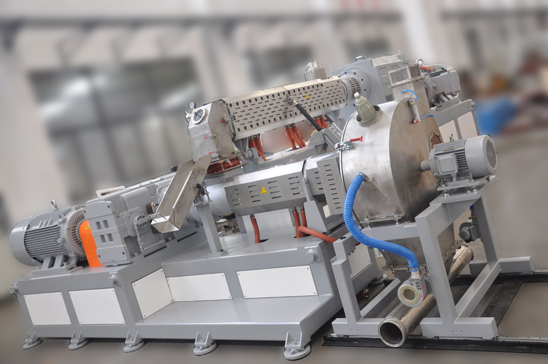

The WKS series Co-Kneader system was specially developed by XINDA for the production of high-capacity PVC compounds. With the new generation Co-Kneader WKS series, the investment and unit production costs are much better than the SJW series while users reach high capacities. At the same time, the WKS system allows the high quality production of different PVC compound types, such as soft and medical type. The system can reach a capacity of about 2500 kg / h, depending on the formulation used.

The WKS system has a shorter screw construction than the other extruder types and the temperature control of the barrel and the screw is entirely achieved with oil. Thus, the temperatures are controlled more effectively and the product quality is increased accordingly.

Newly developed larger Do/Di, optimized screw/barrel design for PVC, improved mixing capability and low barrel pressure ensure low process temperatures and low energy consumption.

In the WKS system, we use our exclusive eccentric head cutting system. This cutting system helps to produce stable production at high capacities.

Technical Specs. ;

| Model |

WKS-100 |

WKS-120 |

| Screw Diameter |

φ113.5~98 |

φ120~132 |

| Do/Di |

1.54~1.74 |

15 - 22 |

| L/D |

15 |

15 |

| Max. Screw Speed |

600 rpm |

600 rpm |

| Main Motor Power |

220 kw |

280 kw |

| Second Stage Screw Diameter |

200 mm |

220 mm |

| Second Stage L/D |

5 |

5 |

| Second Stage Max. Screw Speed |

60 rpm |

60 rpm |

| Second Stage Motor Power |

75 kw |

90 kw |

| Reference Capacity |

1500-1800 |

1800-2500 |