Videos :

Co-Kneader Working Principle

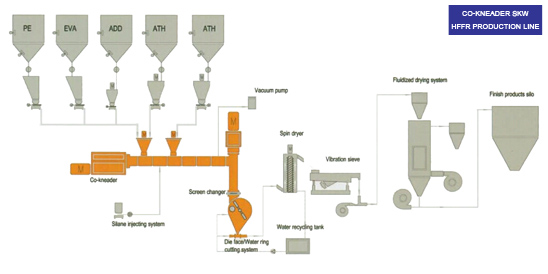

Co-Kneader HFFR Cable Compound Line (Grav. Feeders)

Co-Kneader PVC Compound Line (100PVC+160CaCO3)

Co-Kneader PVC Compound Line Test (Medical Grade PVC)

Co-Kneader Masterbatch Line

Co-Kneader Compound Line

(Eccentric Die Face Cutting)

Co-Kneader Compound Line

(Underwater Cutting)

Co-Kneader Compound Line

(Die Face Cutting) |

|

XINDA - The Birthplace of China's First Co-Kneader... |

|

As the latest technology of Xinda, New Generation Co-Kneader was named as SKW series. This new technology occurs better dispersion by working together with rows of kneading pins on the liners. Also, there will be less friction heat and less energy consumption owing to the New Generation Co-Kneader technology.

The optional equipments of SKW serials (such as oil thermoregulator heating/cooling system, eccentric cutting system, Mayr (German) or Compomac (Italy) torque limiter...) are standard equipments for SKW serials of Co-Kneader.

| APPLICATIONS |

CABLE COMPOUNDS |

MASTERBATCH |

HFFR |

High Concantrated Color Masterbatch |

XLPE |

Black and White Masterbatch |

Semi-Conductive Compounds |

High Loading Filler Masterbatch |

Black Sheathing |

PET / PP / PA Fiber Masterbatch |

Technical Features;

| Model |

SKW-85 |

SKW-105 |

SKW-125 |

| Screw Diameter |

85 mm |

105 mm |

125 mm |

| L/D |

15 - 22 |

15 - 22 |

15 - 22 |

| Max. Screw Speed |

600 rpm |

600 rpm |

600 rpm |

| Main Motor Power |

110 - 160 kw |

200 - 280 kw |

350 - 450 kw |

| Second Stage Screw Diameter |

150 mm |

180 mm |

220 mm |

| Second Stage L/D |

7 |

7 |

7 |

| Second Stage Max. Screw Speed |

60 rpm |

60 rpm |

60 rpm |

| Second Stage Motor Power |

55 kw |

75 kw |

110 kw |

Refference Capacities;

| |

SKW-85 |

SKW-105 |

SKW-125 |

| HFFR Cable Compounds |

200 - 400 |

500 - 800 |

800 - 1500 |

| Black Sheathing |

200 - 400 |

500 - 800 |

800 - 1500 |

| Semi-Conductive Insulating Compouns |

200 - 400 |

500 - 800 |

800 - 1500 |

| Silane XLPE Cable Compounds |

200 - 400 |

500 - 800 |

800 - 1500 |

| High Concetrated Color Masterbatch |

150 - 350 |

400 - 700 |

700 - 1200 |

| Carbon Black Masterbatch |

150 - 350 |

400 - 700 |

700 - 1200 |

| High Loading Filler Masterbatch |

200 - 400 |

600 - 1000 |

900 - 1600 |

| Fiber Reinforced Masterbatch |

150 - 350 |

400 - 700 |

700 - 1200 |

HFFR Cable Compound Production Layout;

Advantages;

- Less process temperatures, less energy consumption,

- Extremely homogenous mixing,

- Full self-wiping without any dead point,

- Dispersive mixing without destroying delicate fillers,

- High volumetric loadings of fillers and additives,

- Efficient blending of liquid components,

- Broad application for compounding without changing hardware,

- Axially opened split barrel quarantees ease of cleaning and fast maintenance,

- Replacement parts such as screws, liners and pins can be change individually. All are modular.

|

|

|