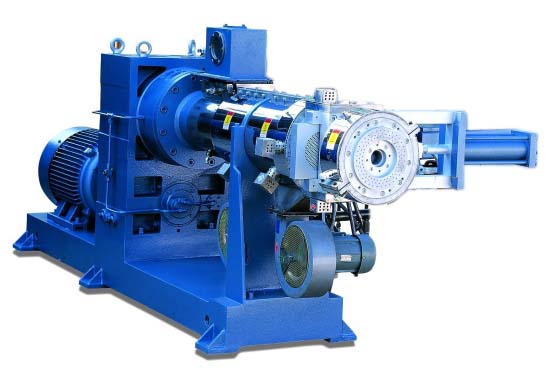

The basic mechanical parts such as main frame, gearbox, screw, barrel, etc. are made by ourself. Motor drivers, PLC-touch screen and low voltage electric equipments are SIEMENS (China). Temperature control systems are Omron (Japan) veya RKC (Japan). We can produce various diameters till 200 mm. There are electrical heaters and air or water cooling systems. Each section's temperature can be control seperately. Side feeder, hydraulic screen changer, vacuum and various cutting systems can be integrated.

Screen Changer:

Vacuum Degassing :

Feeding Systems :

- Volumetric feeders

- Gravimetric feeders

- Liquid feeders

- Side feeders

Optional Cutting/Cooling Systems:

- Die face hot cutting with air cooling

- Eccentric die face cutting with water sprey

- Strand cuttng with water cooling

- Water-Ring die face cutting

- Under water cutting

XINDA & K-TRON COLORMAX (China)

XINDA uses K-tron (China) feeding and pelletizing systems.

K-tron is the best producer in the World for feeders and anchillary parts. K-tron Colormax Systems is a division of Coperion K-Tron.

- K-tron gravimetric feeding systems

- K-tron gravimetric liquid injection system

- K-tron volumetric feeding systems

- K-tron pelletize